When we think about vehicle safety, brakes are often the first thing that comes to mind. But have you ever wondered what makes a braking system truly reliable? The answer lies in its core components—each playing a critical role in ensuring smooth deceleration, precise control, and, most importantly, passenger safety. In this article, we’ll dive deep into the key parts of a brake system, how they work together, and why they’re essential for every vehicle on the road.

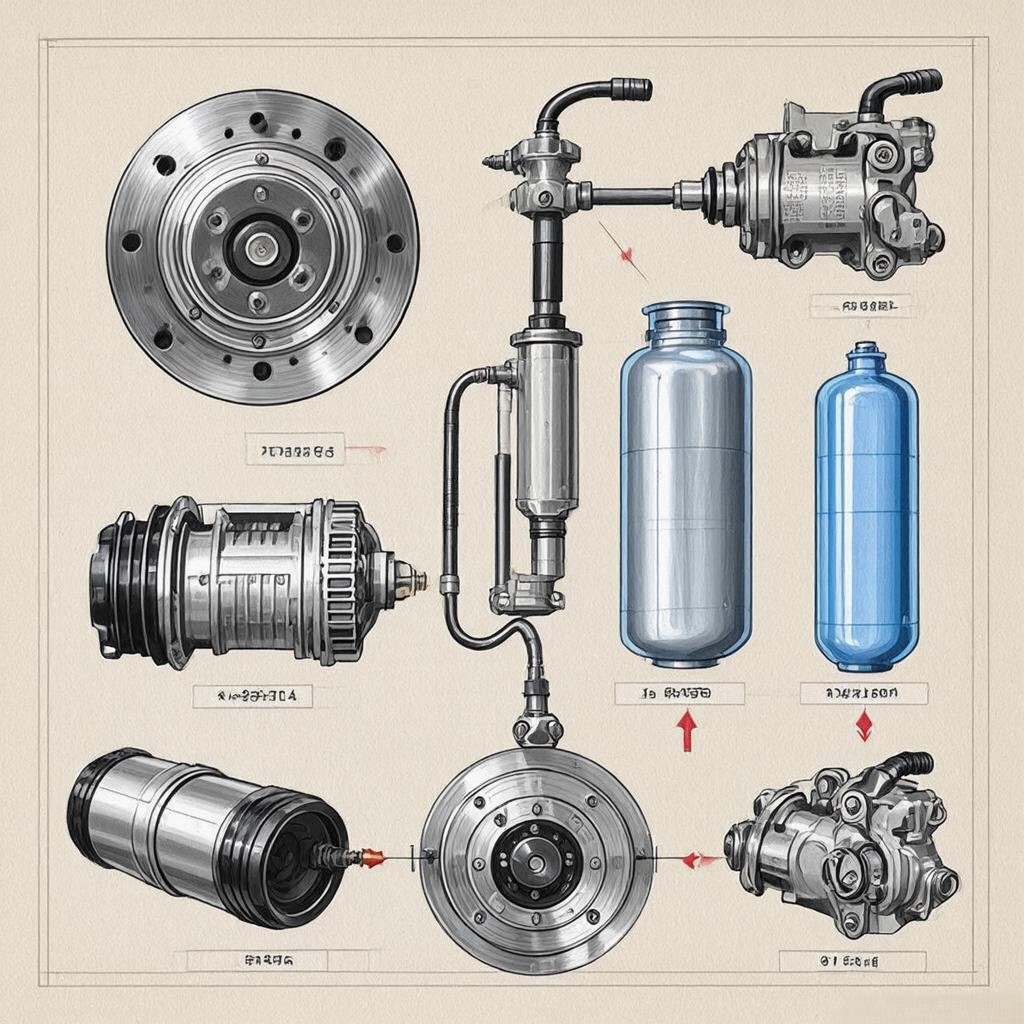

1. Brake Pads and Rotors: The Friction Duo

At the heart of any braking system are the brake pads and rotors. When you press the brake pedal, hydraulic pressure forces the brake pads against the rotating rotors, creating friction that slows down the wheels.

- Brake Pads: Made from composite materials (ceramic, semi-metallic, or organic), they wear down over time and need regular replacement.

- Rotors: Typically made of cast iron or composite metals, they dissipate heat generated during braking. Warped or excessively worn rotors can lead to vibrations and reduced braking efficiency.

Why they matter: High-quality pads and rotors ensure consistent stopping power and minimize brake fade under heavy use.

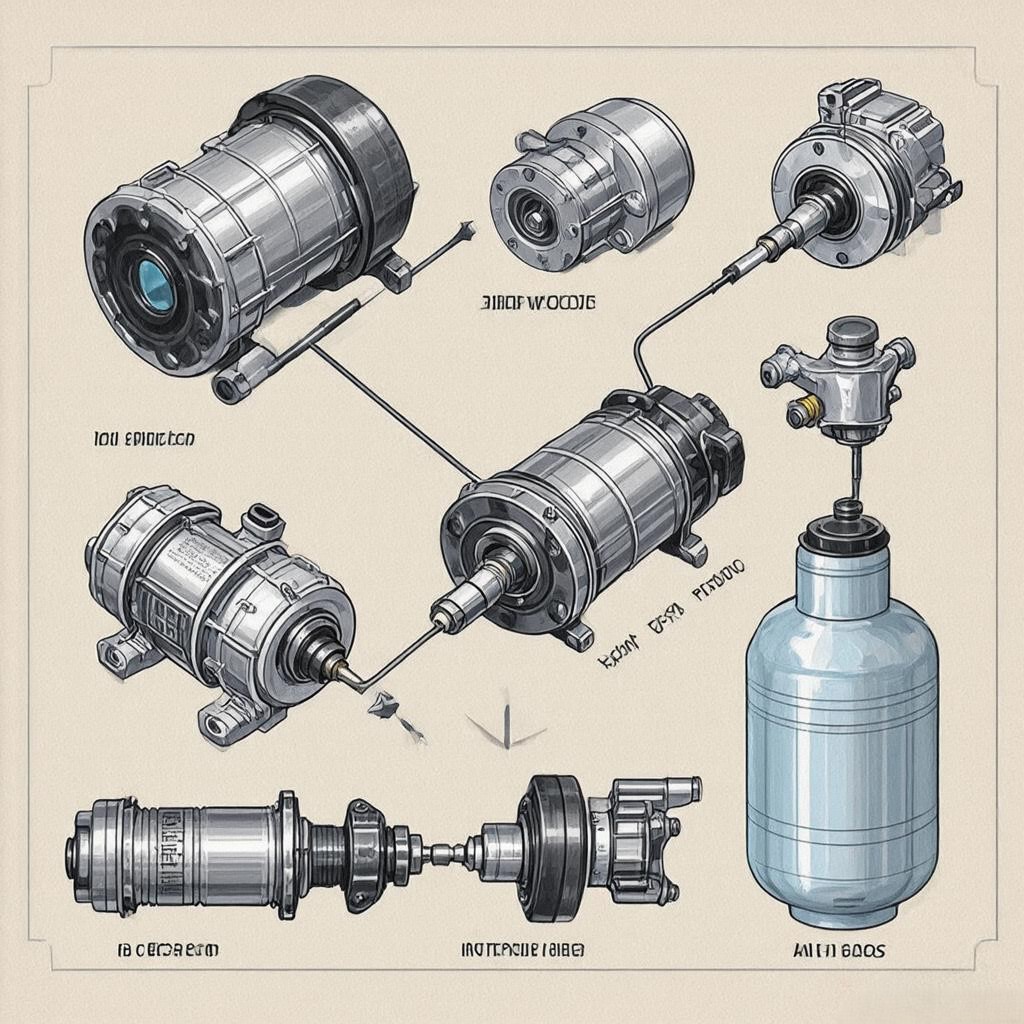

2. Brake Calipers: The Force Multipliers

Brake calipers house the brake pads and apply pressure to them when braking. They come in two main types:

- Floating Calipers: Move inward and outward, pressing the inner pad against the rotor.

- Fixed Calipers: Have pistons on both sides, providing more even pressure and better performance.

Why they matter: A well-functioning caliper ensures even pad wear and optimal braking force distribution.

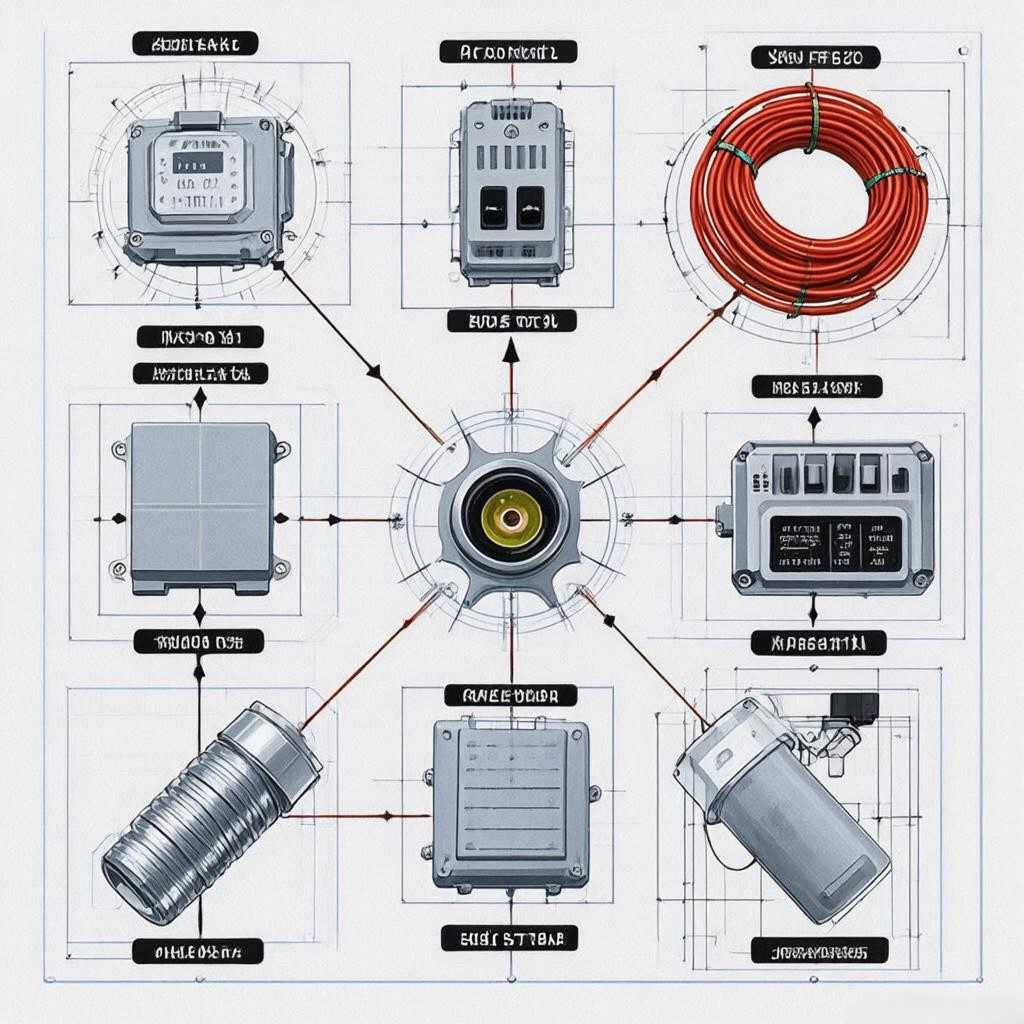

3. Brake Lines and Hoses: The Hydraulic Highway

Brake fluid travels through steel brake lines and rubber hoses to transfer force from the master cylinder to the calipers.

- Steel Lines: Durable and resistant to expansion under pressure.

- Rubber Hoses: Flexible, allowing movement between suspension components.

Why they matter: Leaks or cracks in these lines can lead to brake failure, making regular inspections crucial.

4. Master Cylinder: The Pressure Generator

The master cylinder converts foot pressure on the brake pedal into hydraulic pressure, which is then sent to the wheels.

- Single-Circuit vs. Dual-Circuit: Modern vehicles use dual-circuit systems for redundancy—if one circuit fails, the other still provides braking power.

- Brake Fluid Reservoir: Stores hydraulic fluid and ensures a steady supply.

Why it matters: A failing master cylinder can lead to spongy brakes or complete brake loss.

5. ABS (Anti-lock Braking System): Preventing Wheel Lockup

ABS is a safety system that prevents wheels from locking up during hard braking, allowing the driver to maintain steering control.

- ABS Module: Processes wheel speed sensor data and modulates brake pressure.

- Speed Sensors: Monitor individual wheel rotation speeds.

Why it matters: ABS significantly reduces stopping distances on slippery surfaces and enhances vehicle stability.

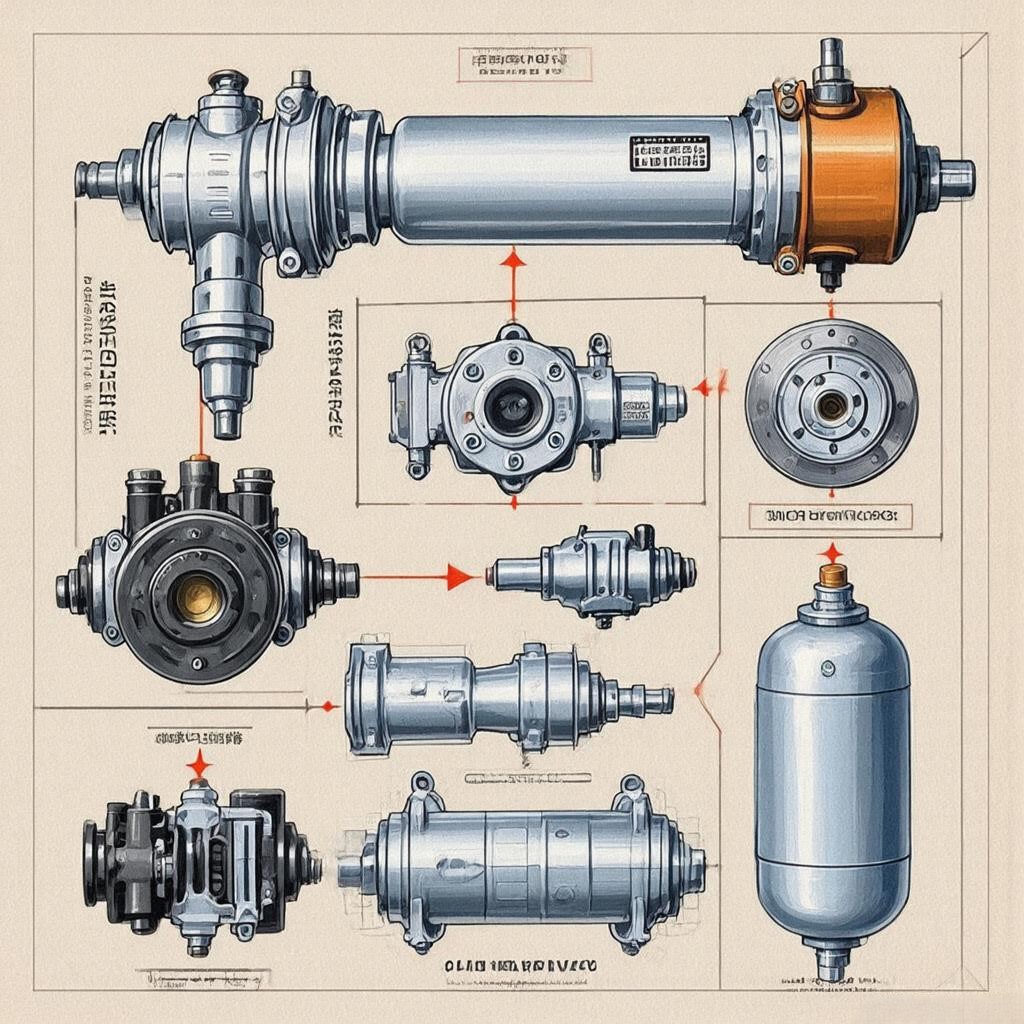

6. Parking Brake (Handbrake/Electronic Brake): Holding the Vehicle in Place

The parking brake ensures the vehicle stays stationary when parked.

- Mechanical Parking Brake: Uses cables to engage rear brakes.

- Electronic Parking Brake (EPB): Uses electric motors for activation, often with auto-hold functionality.

Why it matters: A malfunctioning parking brake can lead to rollaway accidents.

7. Brake Booster: Reducing Pedal Effort

The brake booster amplifies the force applied to the brake pedal, making braking easier—especially at low speeds.

- Vacuum-Assisted Boosters: Most common in gasoline engines.

- Hydraulic Boosters: Used in diesel vehicles or high-performance cars.

Why it matters: Without a booster, stopping a vehicle would require immense pedal pressure.

8. Drum Brakes (Where Still Used): Cost-Effective Stopping Power

While disc brakes dominate modern vehicles, some still use drum brakes—especially on rear wheels.

- Drum and Shoes: When braking, brake shoes press against the inner drum surface.

- Self-Adjusting Mechanism: Compensates for wear over time.

Why they matter: Drum brakes are cheaper to manufacture and effective for rear-wheel braking.

9. Brake Fluid: The Lifeblood of the System

Brake fluid is a hydraulic fluid that transfers force from the pedal to the brakes.

- DOT 3, DOT 4, DOT 5.1: Different boiling points and chemical compositions.

- Moisture Absorption: Over time, brake fluid absorbs water, reducing boiling resistance and leading to brake fade.

Why it matters: Regular fluid changes (every 2-3 years) prevent corrosion and maintain braking efficiency.

10. Electronic Brakeforce Distribution (EBD): Balancing Brake Pressure

EBD works with ABS to adjust braking force between front and rear wheels based on load distribution.

Why it matters: Ensures optimal stopping power without skidding or loss of control.

Conclusion: Why Brake System Components Matter

Every component in a braking system plays a vital role in ensuring safety. From the friction of brake pads to the precision of ABS, neglecting even one part can compromise stopping power and increase accident risks. Regular maintenance—checking pad wear, fluid levels, and system integrity—is essential for every driver.

Final Thought: Your brakes are the most critical safety feature in your vehicle. Understanding their components helps you appreciate their importance and ensures you keep them in top condition.

Call to Action:

🔧 Have you checked your brake pads recently?

⚠️ Ignoring brake issues can lead to costly repairs—or worse, accidents.

🚗 Schedule a brake inspection today and drive with confidence!

#BrakeSystem #VehicleSafety #ABS #CarMaintenance #DrivingTips #AutomotiveEngineering #BrakeComponents #SafetyFirst