Introduction:

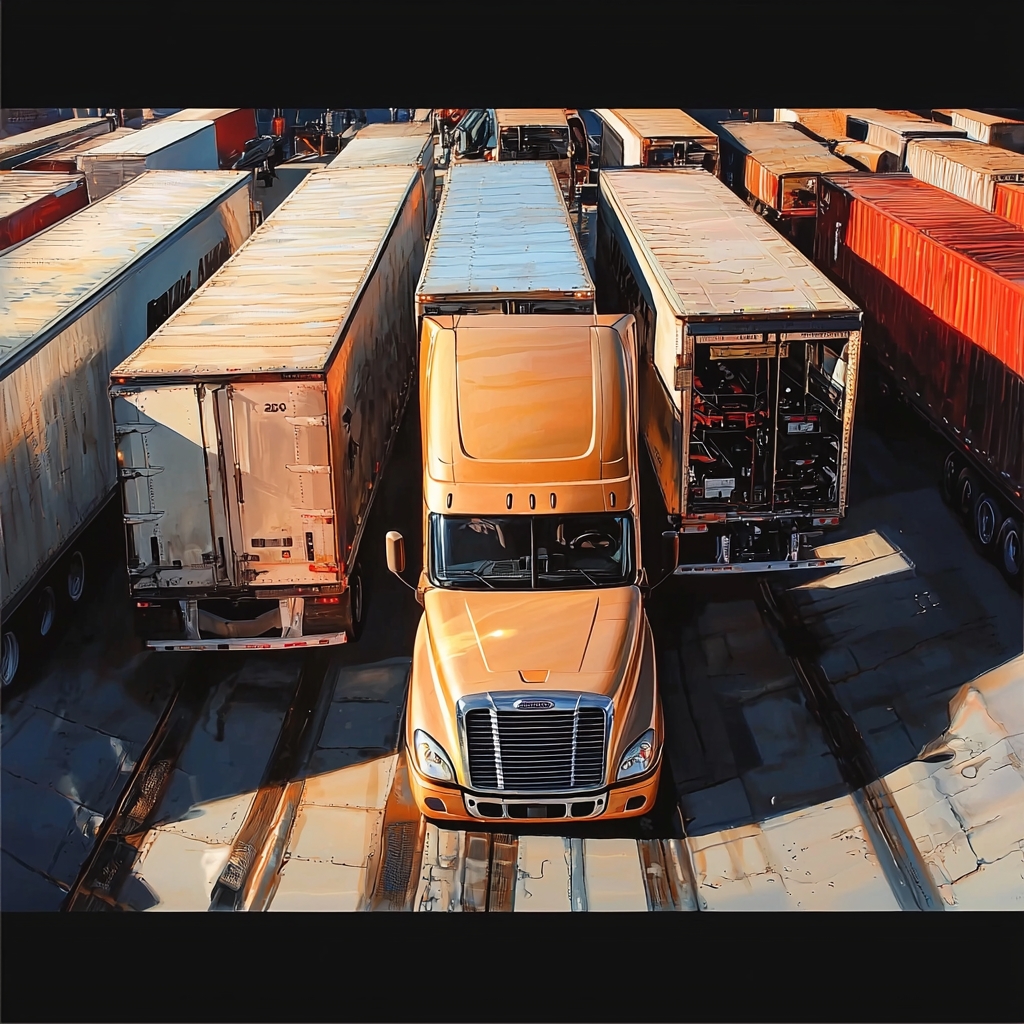

A secure connection between a tractor and trailer’s air brake systems is non-negotiable for safe heavy-duty operations. Faulty gladhands—the pneumatic couplers linking tractor and trailer—can lead to brake lag, pressure loss, or catastrophic detachment. Governed by ISO 7638, these connectors demand strict adherence to color coding, dimensional specs, and seal integrity. This guide dives into gladhands installation, compatibility testing, and synchronization under ISO 7638, empowering fleets to avoid DOT violations and keep highways safe.

Section 1: ISO 7638 Gladhands Overview

Key Requirements:

- Color Coding:

- Red: Emergency/Parking Brake Line (ISO 7638-1).

- Blue: Service Brake Line (ISO 7638-2).

- Yellow: Auxiliary Functions (e.g., trailer ABS).

- Dimensional Specs:

- ½” NPT threads for North America.

- M22x1.5 threads for European trailers.

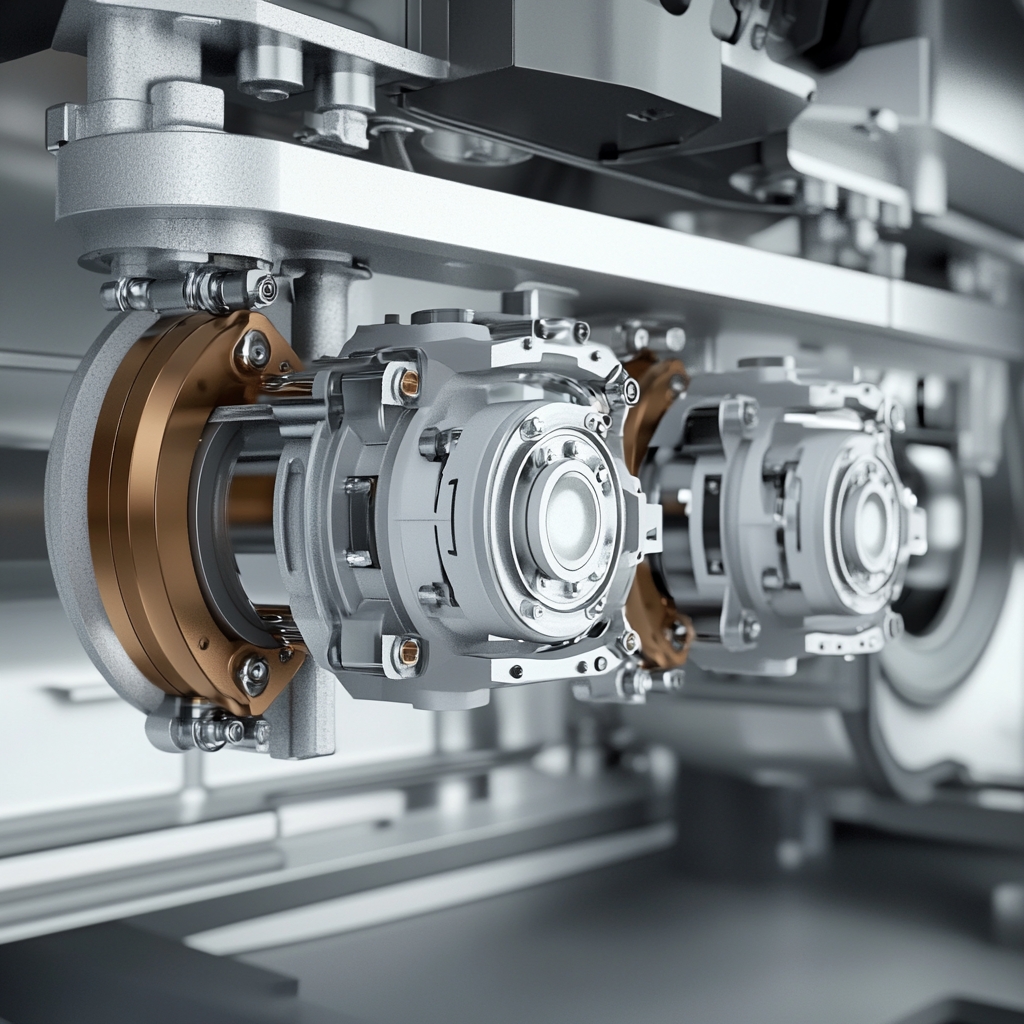

- Seal Design: Double-lip rubber seals to withstand 150 PSI and -40°F to 200°F temperatures.

Safety First:

- Always depressurize air systems before disconnecting gladhands.

- Wear gloves to avoid pinch injuries during coupling.

Section 2: Tools and Materials

Installation Kit:

- ISO 7638-compliant gladhands (e.g., Haldex 247065 for red, 247066 for blue).

- Torque wrench (15–25 ft-lb range).

- Teflon tape or thread sealant (SAE J524-approved).

- Leak detection spray (soapy water or commercial aerosol).

- Pressure gauges (0–200 PSI) for synchronization testing.

Section 3: Step-by-Step Gladhands Installation

Step 1: Verify Compatibility

- Match Colors: Ensure tractor and trailer gladhands follow ISO 7638 color codes.

- Check Threads: Confirm NPT vs. M22 compatibility—mismatched threads cause cross-threading.

Pro Tip: Use adapters (e.g., Dixon ½” NPT to M22) for cross-regional trailers.

Step 2: Prepare Threads

- Clean male/female threads with a wire brush.

- Apply Teflon tape clockwise (2–3 wraps) or thread sealant.

Step 3: Torque Connections

- Hand-tighten gladhands, then torque to 20 ft-lb.

- Avoid over-tightening—it deforms seals and causes leaks.

Section 4: Seal Integrity Testing

Step 4: Pressure Test

- Charge the tractor’s air system to 120 PSI.

- Connect gladhands and trailer lines.

- Monitor pressure for 5 minutes—drop >2 PSI indicates leaks.

Step 5: Soapy Water Test

- Spray soap solution on connected gladhands.

- Bubbles reveal leaks at threads or seals.

Fix Leaks:

- Replace cracked seals (e.g., Timken 569947).

- Reapply thread sealant and retorque.

Section 5: Brake Synchronization Testing

Step 6: Primary/Secondary Circuit Sync

- Primary Circuit (Blue):

- Apply 60 PSI via brake pedal. Trailer service brakes should engage within 0.3 seconds.

- Emergency Circuit (Red):

- Activate parking brake. Trailer brakes must lock within 1 second.

Step 7: Auxiliary Line Validation (Yellow)

- Test trailer ABS signal continuity with a multimeter (expected: 12V with ignition on).

- Use a diagnostic scanner to confirm ABS module communication.

Section 6: Common Failures and Fixes

Problem 1: Cross-Threaded Gladhands

- Symptoms: Difficulty hand-tightening, air leaks.

- Fix: Replace damaged gladhands and threads.

Problem 2: Seal Degradation

- Causes: UV exposure, chemical corrosion.

- Fix: Install UV-resistant seals (e.g., Parker Hannifin 2-226).

Problem 3: Pressure Lag

- Causes: Undersized air lines or kinked hoses.

- Fix: Upgrade to ½” DOT-approved hoses and reroute lines.

Section 7: Compliance and Documentation

- DOT Inspection Prep: Keep records of gladhands part numbers, torque values, and test results.

- Labeling: Tag gladhands with installation dates and technician initials.

Conclusion

ISO 7638 isn’t just a regulatory hoop—it’s a blueprint for fail-safe tractor-trailer braking. By rigorously testing gladhands compatibility, seal integrity, and synchronization, fleets can prevent roadside inspections from turning into costly shutdowns. Remember: A 10-minute pressure test today could avert a jackknife tomorrow.

Upgrade Your Fleet: Explore ACME’s ISO 7638-certified gladhands kits here, featuring pre-lubricated seals and corrosion-resistant alloys.